It's the end of the month. For most of us that means time to work on our monthly quality reports. As I tally up the defects (sorry, nonconformances) against production, by category, by plant, by month; my mind starts thinking about something I learned at church.

In the Catholic faith, we are taught that sins are divided into two categories: mortal and venial. Mortal sins are serious offenses against God. Venial sins are pardonable, lesser offenses. Mortal sins are split into two degrees of seriousness, spiritual sins and carnal sins. Of course, as this topic was being discussed, guess what the first thing that came to my mind was?

"Hey, this is just like quality defects (nonconformances) at work: Critical, Major and Minor defects. We track them in great detail on the monthly quality reports."

Imagine God reviewing our sins on a monthly basis like a quality report.

"Ok Mike, let's go over your sin charts for last month. Looks like under Mortal-Spiritual sins (Criticals) your are at 0 PPM...Very Good. It says here that your Mortal-Carnal sins (Majors) are also at 0 PPM, excellent month to month trend for the fiscal year. Keep up the good work."

What in MY name is going on with your venial (minor) sins? You are posting a 13,568 PPM for the month. Just look on Friday the 16th. Good ME, you had a big spike on that night."

"Can you explain what were the root causes attributing to this spike?"

"What are your countermeasures?"

"I expect you to fill out this Corrective/Preventative Action Form out completely and return it directly to me within 10 glory days."

"Overall, Mike, I am pleased with your progress however you have to focus on your venial sin PPM. Thank ME that I possess infinite forgiveness for all sins that your soul is saved."

Funny as it may seem, I just don't believe it works out that way. As humans, we are granted the gifts of reason and free-will. Therefore, we can choose. We also can easily rationalize our thoughts and actions, putting things into degrees so they don't seem so bad. For our mortal minds, I guess that helps us sleep at night.

According to the Bible (NAB John 8:11), "Then Jesus said, "Neither do I condemn you, Go and from now on do not sin anymore." Jesus did not say, go and do not commit any spiritual sins, keep your mortal sins down and try to stay below "xx" number of venial sins. Based on this passage, all sins are the same in that all sins are undesirable and we are directed to simply sin no more.

Looking at the quality world on earth, we should have the same belief in that, just like with sin, all defects (nonconformances) are undesirable. Breaking defects into categories is a waste of effort.

For business products and services, instead of judgment day before God, we answer to our customers. Unlike God, our customers are not so forgiving. They do not possess infinite capacity to forgive us for our nonconformances (sins). They will abandon us for others and we will no longer have a relationship with them. In other words, our business will go to hell.

With this in mind, we should not worry so much about what constitutes a major or minor nonconformance. We should not waste time and effort putting a spin on degrees of our quality performance.

To repeat the words of Jesus, we should "Go and from now on do not sin anymore."

Mike Wroblewski's blog on developing a Kaizen Mind focused on Lean Manufacturing, Lean Healthcare, Lean Government and Six Sigma Quality

Friday, September 30, 2005

Wednesday, September 28, 2005

How do I start on the Lean Journey?

This question is by far the most popular in any discussion on the implementation of lean manufacturing. If you are thinking about starting out on your quest towards becoming lean, seek knowledge first.

Knowledge about lean can come from talking with others about their lean experiences, reading lean books (I highly recommend "The Toyota Way" by Jeffrey Liker), examining company case studies on their lean journey and visiting other companies using the lean approach. Other opportunities to gain knowledge include using consultants, exploring the internet, joining a lean group like The Paradigm Network (reference earlier post) or even participating in a kaizen event hosted by another company. With this knowledge, you can make a determination if the lean approach is the right direction for you.

The next step is to plan and prepare your best course of action that makes sense for your company and matches your lean vision. All companies have unique situations, products, markets, resources, talents, etc. Your plans should fit your particular needs and capabilities. It really does not matter if you pick 5S or value stream mapping (or any other area) to start. It really does not matter which department or plant to start. Go with a lean plan based on what you have learned and what feels right. Now pick a date to start, the time for action must begin!

Knowledge is power.

Action gets results.

Knowledge + Action = Powerful Results

One additional note: Regardless of how you begin, everybody that pursues lean makes mistakes, hits roadblocks, experiences some failures and achieves some successes. What is important is that you have begun the quest!

Knowledge about lean can come from talking with others about their lean experiences, reading lean books (I highly recommend "The Toyota Way" by Jeffrey Liker), examining company case studies on their lean journey and visiting other companies using the lean approach. Other opportunities to gain knowledge include using consultants, exploring the internet, joining a lean group like The Paradigm Network (reference earlier post) or even participating in a kaizen event hosted by another company. With this knowledge, you can make a determination if the lean approach is the right direction for you.

The next step is to plan and prepare your best course of action that makes sense for your company and matches your lean vision. All companies have unique situations, products, markets, resources, talents, etc. Your plans should fit your particular needs and capabilities. It really does not matter if you pick 5S or value stream mapping (or any other area) to start. It really does not matter which department or plant to start. Go with a lean plan based on what you have learned and what feels right. Now pick a date to start, the time for action must begin!

Knowledge is power.

Action gets results.

Knowledge + Action = Powerful Results

One additional note: Regardless of how you begin, everybody that pursues lean makes mistakes, hits roadblocks, experiences some failures and achieves some successes. What is important is that you have begun the quest!

Tuesday, September 27, 2005

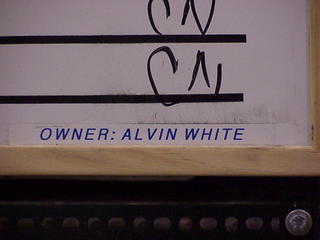

Who owns the bulletin boards?

Whenever I visit a plant, I can not help but wander over to one of the bulletin boards. What do you think I see most of the time? Most bulletin boards are filled with out of date information and cluttered beyond belief. As a result, most people just ignore the boards all together.

One factor is that there is no ownership. In the transformation to become lean, ownership and responsibility are required elements. Without ownership, things like bulletin boards are neglected. Unfortunately, neglect is not just limited to bulletin boards in many manufacturing plants across America.

One easy way to solve this problem is to actually post the owners name on the board. Every piece of information on the board should have someone designated as the owner to keep it in order and current. Soon after this simple 5-S improvement, the boards will become a usable source of information again.

Monday, September 26, 2005

The 50/50 Approach to Finding a Root Cause

Recently, I was spending the day going to the gemba by being a guest inspector on the assembly line. It did not take very long to see what many of the problems were in the process. One particular nonconformance that caught my attention was a persistent scratch found in the same spot on nearly 50% of the metal units. Following the established methods, I oscillated the spot and pushed the unit to the next department.

The next day, I met with the regular inspector and shared what I observed. He confirmed that this scratch was pretty common. Since it was an easy 5 second fix, nobody paid it too much attention to it. (Does this sound familiar?)

I knew that I could locate the root cause of this scratch because it was somewhat consistent and easy to see. It became a new mission and I decided to use the 50/50 Approach. This technique is pretty simple to use. Starting at the front of the line, I checked for the scratch and found none. So I split the distance between the inspection station and the front of the line. Here, at the middle of the line, I found the scratch.

Then I split the distance again, between the front of the line and the middle. At this station I found the scratch again. I continued splitting the line and moving upstream or downstream depending if the scratch was present or not. After a few rounds, I narrowed the presence of the scratch to a single station.

Focusing on this station, I saw exactly what caused the scratch. Ironically, it was a quality check. A metal square was used to check for squareness and the metal to metal contact created the scratch. It is amazing to actually follow a process and see right before your eyes the cause of a defect. A simple, homemade plastic cover on the square eliminated the problem.

By using a 50/50 approach, in some cases like this one, its easy to whittle down to the root cause. Try it sometime.

The next day, I met with the regular inspector and shared what I observed. He confirmed that this scratch was pretty common. Since it was an easy 5 second fix, nobody paid it too much attention to it. (Does this sound familiar?)

I knew that I could locate the root cause of this scratch because it was somewhat consistent and easy to see. It became a new mission and I decided to use the 50/50 Approach. This technique is pretty simple to use. Starting at the front of the line, I checked for the scratch and found none. So I split the distance between the inspection station and the front of the line. Here, at the middle of the line, I found the scratch.

Then I split the distance again, between the front of the line and the middle. At this station I found the scratch again. I continued splitting the line and moving upstream or downstream depending if the scratch was present or not. After a few rounds, I narrowed the presence of the scratch to a single station.

Focusing on this station, I saw exactly what caused the scratch. Ironically, it was a quality check. A metal square was used to check for squareness and the metal to metal contact created the scratch. It is amazing to actually follow a process and see right before your eyes the cause of a defect. A simple, homemade plastic cover on the square eliminated the problem.

By using a 50/50 approach, in some cases like this one, its easy to whittle down to the root cause. Try it sometime.

Sunday, September 25, 2005

Point Kaizen

One the most powerful and exciting Lean improvement techniques is a Kaizen event. Typically, only one week in duration, a kaizen event is where a team works feverishly through a targeted area implementing process improvements. In addition to a great sense of accomplishment, a highly energized team gets results and is motivated for more!

A variation of this common version of Kaizen is what I call a "Point Kaizen". Here is how it works. A point kaizen is focused on one small improvement to be implemented in a matter of a few hours by a team of one or two people already trained in using lean tools. Using all the same steps and techniques that occur in a week long Kaizen only highly condensed. The idea is to complete a single point improvement as quickly as possible.

An example of a recent point kaizen I completed occurred at a final inspection station. I saw that the inspector was placing a red nonconforming tag on a defective unit and pulling the unit off line for repair. The red tag was single sided printed card stock. The strange thing I noticed is the inspector was not using the printed side at all. He used the blank side to write the type of defect and taped the tag on the unit.

In addition, there were at least a dozen cards with various defects written on them taped all around the inspection station. I asked the inspector, "Why do you have all these tags here?". He said, "These tag are expensive so I try to reuse them". The tags had no dates, names or any other information.

In just a few minutes of asking why? five times and having different employees explain the problems with this system ( tags falling off, tags too complex, not sure if units are repaired, how long it has been sitting in repair, etc.) , I quickly evaluated the current process and potential improvement.

I replaced the red tag that was ordered from a printer at $0.06 to a simple word document formated tag printed on red paper at $0.005. The tag could be printed as needed in small quantities versus minimum lot size in the thousands from the printer. The simple form was easy to fill out with name, date and defect. It also had a sign off for completed repair. After use, it was trashed. Net results were an improved nonconformance identification process at about $1,000 annual savings all completed in under 2 hours. It also helped 5-S the inspection station.

A variation of this common version of Kaizen is what I call a "Point Kaizen". Here is how it works. A point kaizen is focused on one small improvement to be implemented in a matter of a few hours by a team of one or two people already trained in using lean tools. Using all the same steps and techniques that occur in a week long Kaizen only highly condensed. The idea is to complete a single point improvement as quickly as possible.

An example of a recent point kaizen I completed occurred at a final inspection station. I saw that the inspector was placing a red nonconforming tag on a defective unit and pulling the unit off line for repair. The red tag was single sided printed card stock. The strange thing I noticed is the inspector was not using the printed side at all. He used the blank side to write the type of defect and taped the tag on the unit.

In addition, there were at least a dozen cards with various defects written on them taped all around the inspection station. I asked the inspector, "Why do you have all these tags here?". He said, "These tag are expensive so I try to reuse them". The tags had no dates, names or any other information.

In just a few minutes of asking why? five times and having different employees explain the problems with this system ( tags falling off, tags too complex, not sure if units are repaired, how long it has been sitting in repair, etc.) , I quickly evaluated the current process and potential improvement.

I replaced the red tag that was ordered from a printer at $0.06 to a simple word document formated tag printed on red paper at $0.005. The tag could be printed as needed in small quantities versus minimum lot size in the thousands from the printer. The simple form was easy to fill out with name, date and defect. It also had a sign off for completed repair. After use, it was trashed. Net results were an improved nonconformance identification process at about $1,000 annual savings all completed in under 2 hours. It also helped 5-S the inspection station.

Friday, September 23, 2005

The Paradigm Network

Attended the monthly meeting of the Paradigm Network of Central Indiana this morning in Indianapolis. Paradigm is a group consortium of local manufacturers working together to improve their business through lean methods. Our group is led by Mark Ippolito and Bob Thompson, doing an excellent job of helping companies on their lean journey. We covered the topics of lean culture change and sustaining the lean effort. More on that later!

Lean IDEA: Find a local group or start one of your own in your area to share your lean knowledge and experiences. Together we can all gain in strength. If you are from the Indy area and interested in the group, send me an email.

Lean IDEA: Find a local group or start one of your own in your area to share your lean knowledge and experiences. Together we can all gain in strength. If you are from the Indy area and interested in the group, send me an email.

Thursday, September 22, 2005

Any Idiot Can Cut Costs

Everyday it seems that I read about another company cutting costs to regain profitability. This morning it was Sony. According the Associated Press article, Sony will implement a "bold turnaround plan" by cutting 10,000 jobs and slashing factories. This amounts to about a 6% cut in their workforce along with shutting down 11 factories. The article also includes part of the Sony official statement, "These reductions will help streamline our operations and enable us to operate more efficiently". My initial reaction was "Yea, right".

These cost cutting headlines, many times, gets thrown together with the Lean Manufacturing approach to improvement. First point, any headcount reduction as a result of any lean efforts will mean disaster. It will not work. Second point, to regain profitability you need to grow a business and cost cutting is not growth. Finally, any idiot can cut costs. It takes true leadership and teamwork to grow a business.

Another major mistake in trying to implement the lean approach in American business is to focus on the cost cutting tools and not the growth strategy. You MUST have a growth strategy to succeed.

The key is to free up resources through your lean efforts and let them loose to work on the growth opportunities. This can be any number of activities. For example, if you are losing customers, put a group together to help you get them back. Their only goal is to find out what your customers really want and give it to them. Other opportunity areas include PM programs, safety improvements, wellness programs, R&D projects, new products, Six sigma projects, or even process documentation. The focus should be on growth!

In the case of Sony, imagine losing 10,000 employees. From a bottom line standpoint, that could be considered a significant savings on operating expense. But when you lose 10,000 bodies, you also lose their brainpower. Now, just imagine what the brainpower of 10,000 can do when applied to growing the business!

These cost cutting headlines, many times, gets thrown together with the Lean Manufacturing approach to improvement. First point, any headcount reduction as a result of any lean efforts will mean disaster. It will not work. Second point, to regain profitability you need to grow a business and cost cutting is not growth. Finally, any idiot can cut costs. It takes true leadership and teamwork to grow a business.

Another major mistake in trying to implement the lean approach in American business is to focus on the cost cutting tools and not the growth strategy. You MUST have a growth strategy to succeed.

The key is to free up resources through your lean efforts and let them loose to work on the growth opportunities. This can be any number of activities. For example, if you are losing customers, put a group together to help you get them back. Their only goal is to find out what your customers really want and give it to them. Other opportunity areas include PM programs, safety improvements, wellness programs, R&D projects, new products, Six sigma projects, or even process documentation. The focus should be on growth!

In the case of Sony, imagine losing 10,000 employees. From a bottom line standpoint, that could be considered a significant savings on operating expense. But when you lose 10,000 bodies, you also lose their brainpower. Now, just imagine what the brainpower of 10,000 can do when applied to growing the business!

Wednesday, September 21, 2005

Lean Leadership

From the earliest steps of my lean journey, I was told that Upper Management Support was critical to the success of lean. Any lean initiative would be doomed to fail without it. I did not question this wisdom from the "Lean Experts". Lean leadership even sounded logical. How can any effort in business work without management support and approval?

Funny thing, what I learned on my lean journey is that Lean Leadership is not required! (Also, I learned that this is not a guarantee for success either!) The reality is...Management is only interested in RESULTS and not methods. This is especially true in the upper management layers of the organizations where visits to the shop floor are infrequent and rushed.

A common mistake in the lean journey is to first contract with a high paid consultant to teach "lean" to the upper management levels. Following this enlightenment phase, management will publicly state their devotion to lean principles at the "XYZ" company from this day forward, establish strategic lean metrics for year end and tell their managers to hit the goals. After a couple of projects and some inventory cuts, upper management will think that their company is now "lean".

A better approach to Lean Leadership is the bottom up approach. Select a target area within the company, teach the lean principles at the point where the work is done, follow the improvement methodology and GET RESULTS that match with company directions. Along the way, keep management informed of your targets and progress. With success, upper management will become supportive of any method that is working even Lean. Other areas within the company will start to ask "How about us?". Success will create believers and followers. People want to be on the winning team and around success.

Funny thing, what I learned on my lean journey is that Lean Leadership is not required! (Also, I learned that this is not a guarantee for success either!) The reality is...Management is only interested in RESULTS and not methods. This is especially true in the upper management layers of the organizations where visits to the shop floor are infrequent and rushed.

A common mistake in the lean journey is to first contract with a high paid consultant to teach "lean" to the upper management levels. Following this enlightenment phase, management will publicly state their devotion to lean principles at the "XYZ" company from this day forward, establish strategic lean metrics for year end and tell their managers to hit the goals. After a couple of projects and some inventory cuts, upper management will think that their company is now "lean".

A better approach to Lean Leadership is the bottom up approach. Select a target area within the company, teach the lean principles at the point where the work is done, follow the improvement methodology and GET RESULTS that match with company directions. Along the way, keep management informed of your targets and progress. With success, upper management will become supportive of any method that is working even Lean. Other areas within the company will start to ask "How about us?". Success will create believers and followers. People want to be on the winning team and around success.

Boondoggle Everywhere

Welcome to a new blog site dedicated to the elimination of waste in American Business. Using the principles of Lean Manufacturing, Six Sigma and a "just try it" attitude, many issues and topics will be examined, challenged, tried and shared. The end result is to help those who are interested to successfully improve their business or workplace.

One of the best improvement methods is to eliminate waste from the process. From my viewpoint, waste can be seen in just about every single business process. Boondoggle is Everywhere. What is most discouraging is that this waste is generally accepted!

For whatever the reasons (Don't see it, no money, no resources, no time, don't know how, lean is a fad, my company is unique, etc), waste is allowed to exist unchallenged. You can either continue to accept it or join the fight to eliminate it.

One of the best improvement methods is to eliminate waste from the process. From my viewpoint, waste can be seen in just about every single business process. Boondoggle is Everywhere. What is most discouraging is that this waste is generally accepted!

For whatever the reasons (Don't see it, no money, no resources, no time, don't know how, lean is a fad, my company is unique, etc), waste is allowed to exist unchallenged. You can either continue to accept it or join the fight to eliminate it.

Subscribe to:

Comments (Atom)