Whenever I visit a plant, I can not help but wander over to one of the bulletin boards. What do you think I see most of the time? Most bulletin boards are filled with out of date information and cluttered beyond belief. As a result, most people just ignore the boards all together.

One factor is that there is no ownership. In the transformation to become lean, ownership and responsibility are required elements. Without ownership, things like bulletin boards are neglected. Unfortunately, neglect is not just limited to bulletin boards in many manufacturing plants across America.

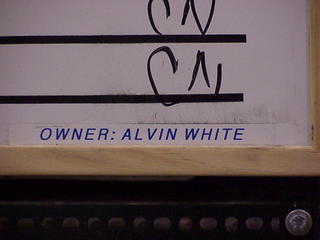

One easy way to solve this problem is to actually post the owners name on the board. Every piece of information on the board should have someone designated as the owner to keep it in order and current. Soon after this simple 5-S improvement, the boards will become a usable source of information again.

2 comments:

Even if there is ownership, you still need leadership to make sure the metrics/boards are being updated. If "Alvin" is the owner and not updating it, the level of supervision/management above Alvin needs to step up and take corrective action when it's not updated. I've seen many companies where the spine/backbone/leaderhip required to make things like that work just wasn't there. Good post though.

Thanks for the comments Mark. The first step is establishing ownership to prevent the gaps created by areas considered "no mans land" so nothing gets done.

The second step as you pointed out is to follow up! In most cases, follow up is manditory or else it is seen as unimportant and becomes neglected again.

Post a Comment